1 . Manufacture and sale of next generation semi-conductor substrate planarization machines (CARE equipment)

A CARE equipment is used to planarize SiC and GaN substrates used in electric vehicles and high-speed telecommunications equipment with atomic precision, utilizing the Catalyst-referred Etching Method (CARE method) proposed by Professor Kazuto Yamauchi and Associate Professor Yasuhisa Sano at Osaka University.

Machine delivered to Nagoya University C-TEFs (CIRFE- Transformative Electronics Facilities)

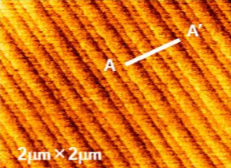

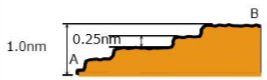

CARE Flattening surface (AFM)

P-V: 0.731 nm

RMS: 0.086 nm

AB cross-section in the diagram on the left (Schematic diagram)

4H-SiC c-axis lattice constant: 1.008 nm

Height of 1 step: 0.252 nm

AB cross-section in the diagram image above (Schematic diagram)

4H-SiC c-axis lattice constant: 1.008 nm

Height of 1 step: 0.252 nm

Ultimate flatness can be achieved

Features of the CARE method

・It is environmentally friendly and reduces cost as processing only uses water

・No processing alteration layers, and improved device performance.

・Unique small-amplitude movement reduces the equipment area to one-quarter (compared to our conventional machine)

2 . CMP(Chemical Mechanical Polishing)Pad-related business

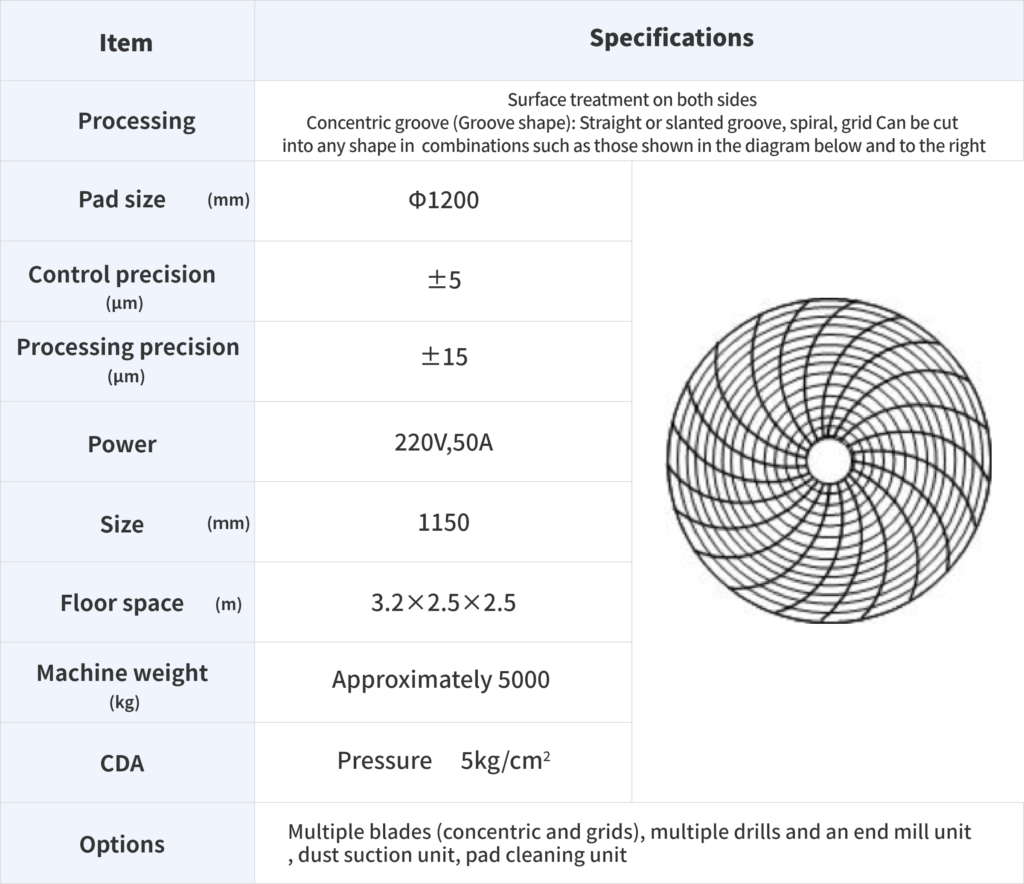

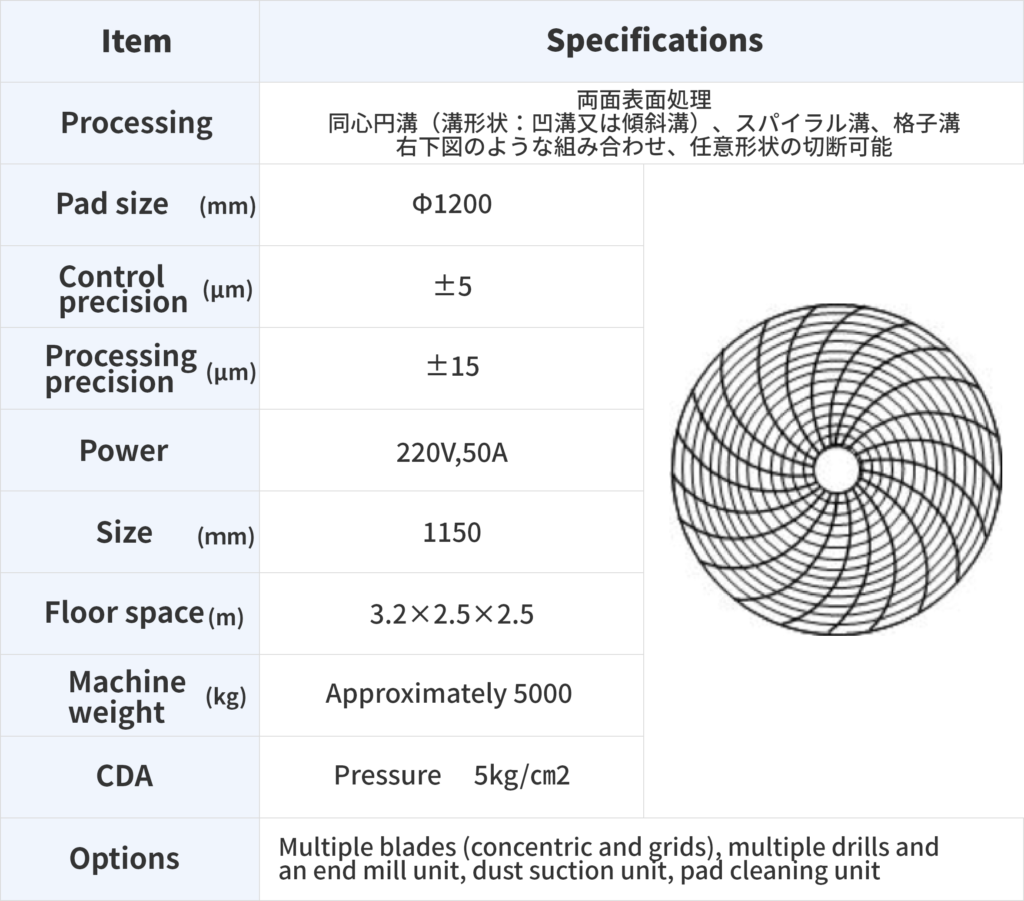

(1)Manufacture of CMP pad processing machines and contract processing

Abrasive resin plates called CMP pads are used to polish semiconductor wafers, and in this key process, the cost of polishing for planarization accounts for approximately 30% of the cost of manufacturing a substrate. Toho Koki Seisakusho is a leader in this field, and can provide customers in Japan and overseas with solutions for their requirements.

Sale of pad processing machines

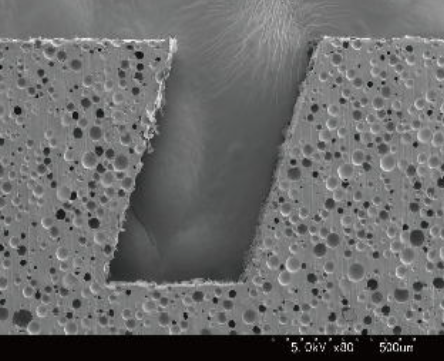

Abrasive pad surface and groove processing

Specialized groove processing

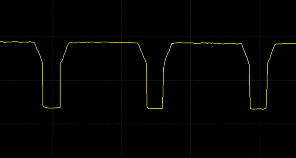

(2)CMP pad inspection machine

3 . Machining of large machine parts

This has been our core business since our foundation. We specialize in the machining of large circular parts, with diameters up to five meters.

Toho Koki Seisakusho has machined critical components for power generation turbines and aerospace aircraft, as well as machining the cable bands for the Akashi Kaikyo Bridge.

Akashi Kaikyo Bridge: Cable machining

World’s longest center span: 2,000 m

Wire diameter: 1,100 mm